For this assignment, my inspiration was the limited methods I had to construct an irregular box.

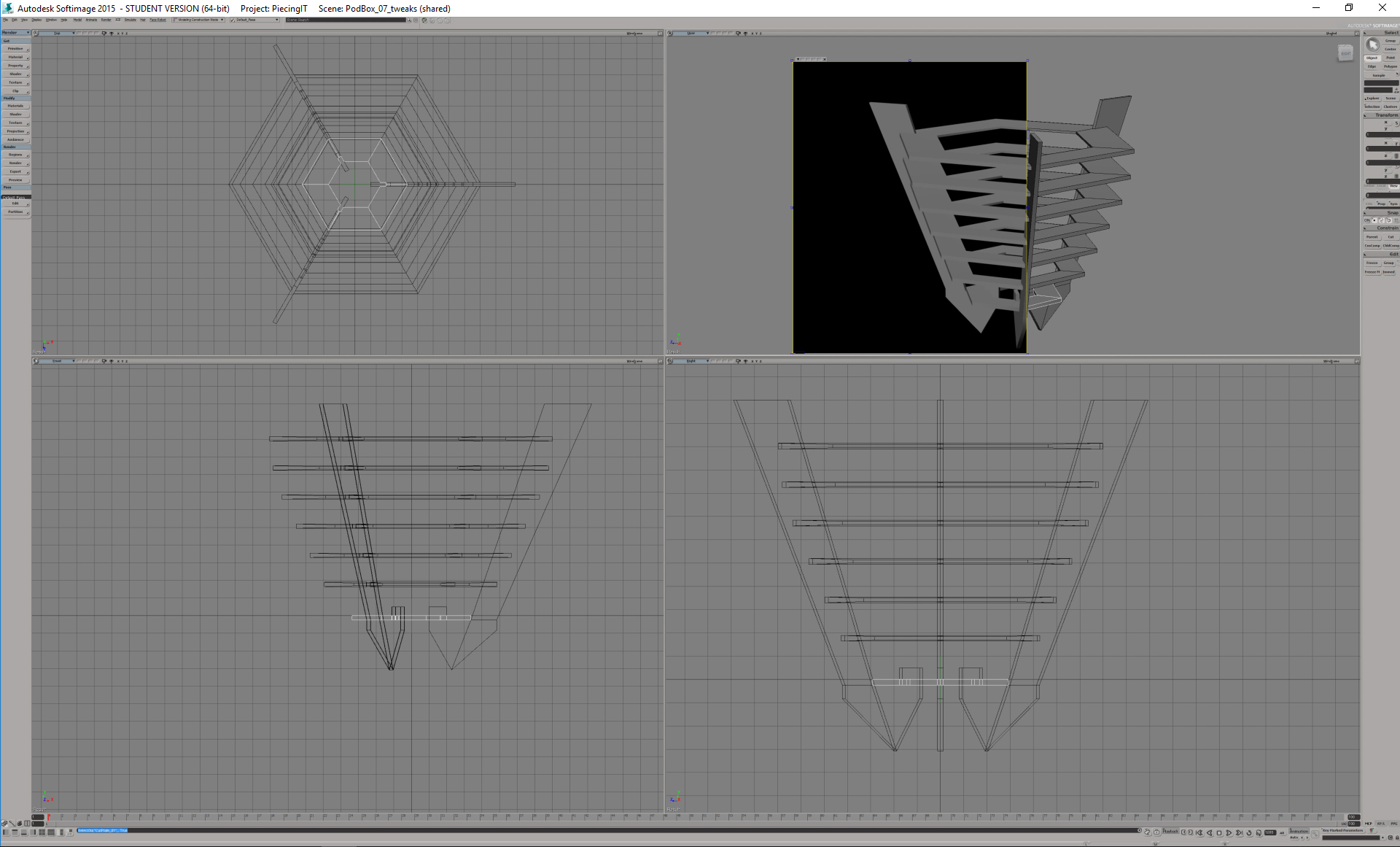

I decided to approach this project in Softimage with extruded polygons. This works well because the methods we have available to fabricate also depends on flat surfaces with a uniform thickness. Or so I thought…

Softimage has no real world base unit to modify (as far as I could tell). The designer has to keep in mind 1 unit in XSI is 1 inch, for example.

I exported my model as 10 objects. Then imported them into 123D. That process was okay but not so obvious for beginners. I made a critical mistake which would come back to haunt me. For some reason the scaling feature is automatically enabled. When I exported the Vector cuts they were not proportional to my other pieces.

I converted the EPS files into the AI formats that the laser print driver natively reads. The actual laser cutting process isn’t too complicated once you’ve gone through it a few times.

I knew prototyping is very important but due to unexpected constraints I went with acrylic and learned an expensive hard lesson. Next time around I know what to expect from this process and will be sure to prototype.